Zmdi-facebook

Zmdi-twitter

Zmdi-youtube-play

Zmdi-instagram

无标题文档

Product Specifications

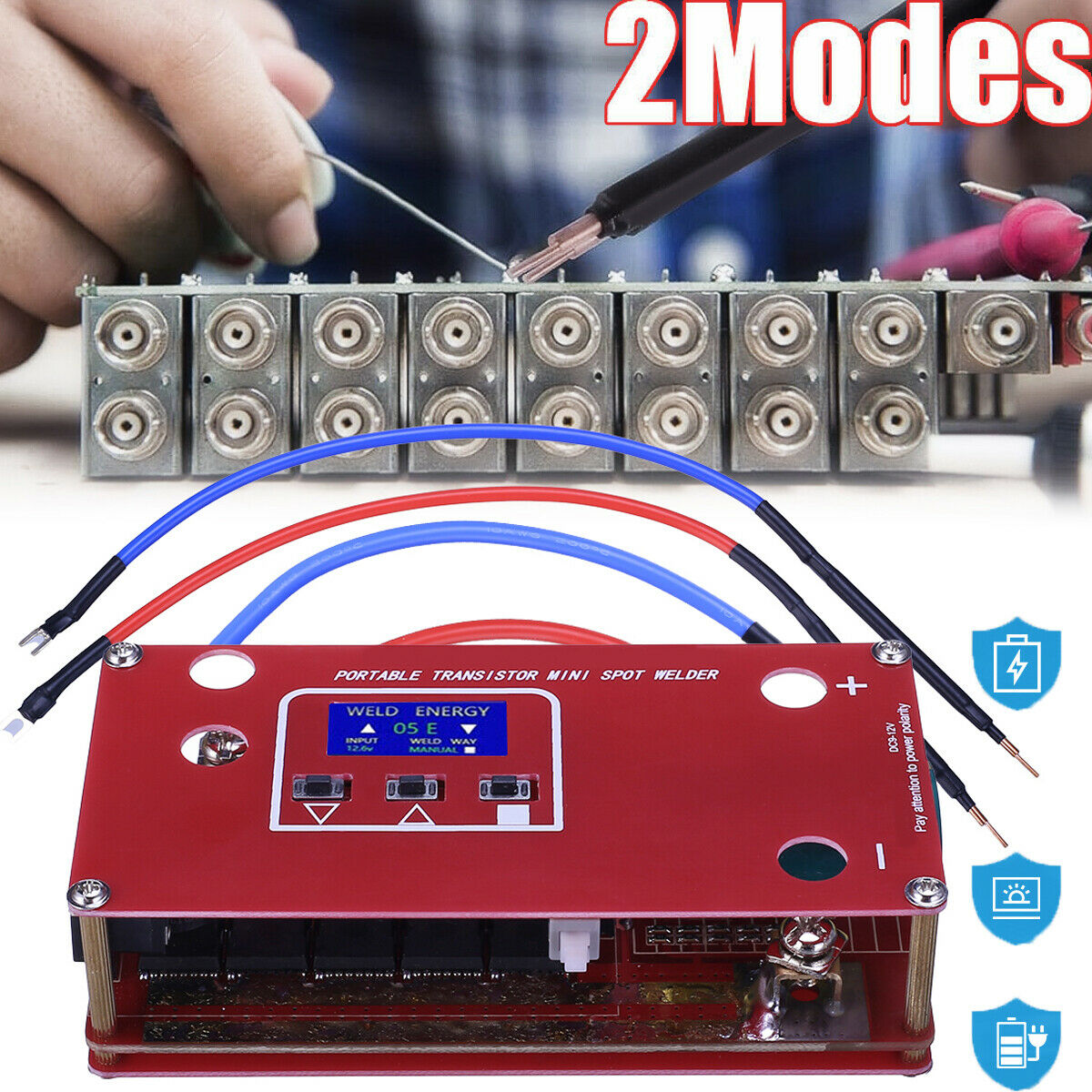

A Wide Selection of Welding Power Supply: Lithium battery power supply or 12V car battery.

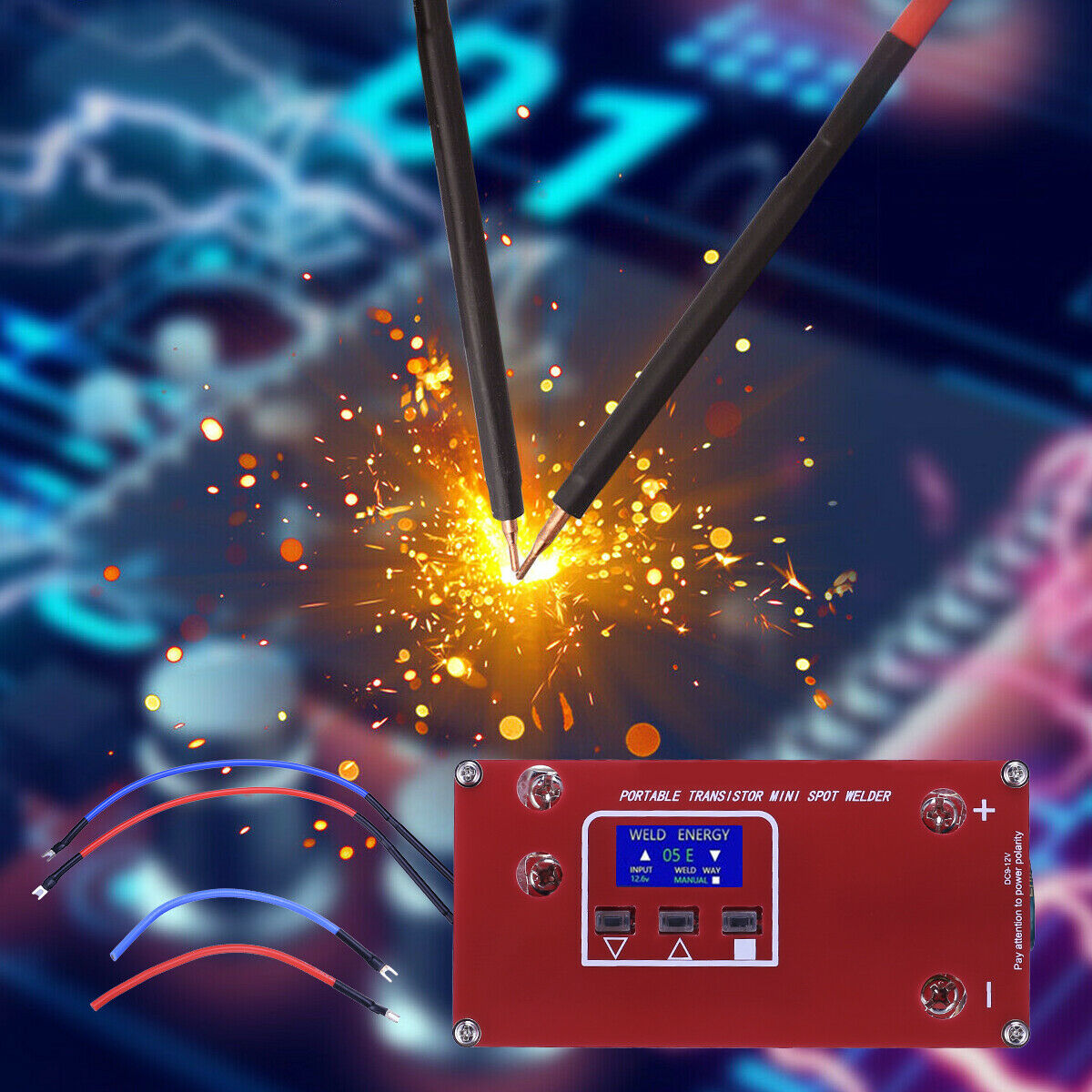

The controller is controlled by a single-chip microcomputer, and the output pulse is accurate to ensure the welding quality.

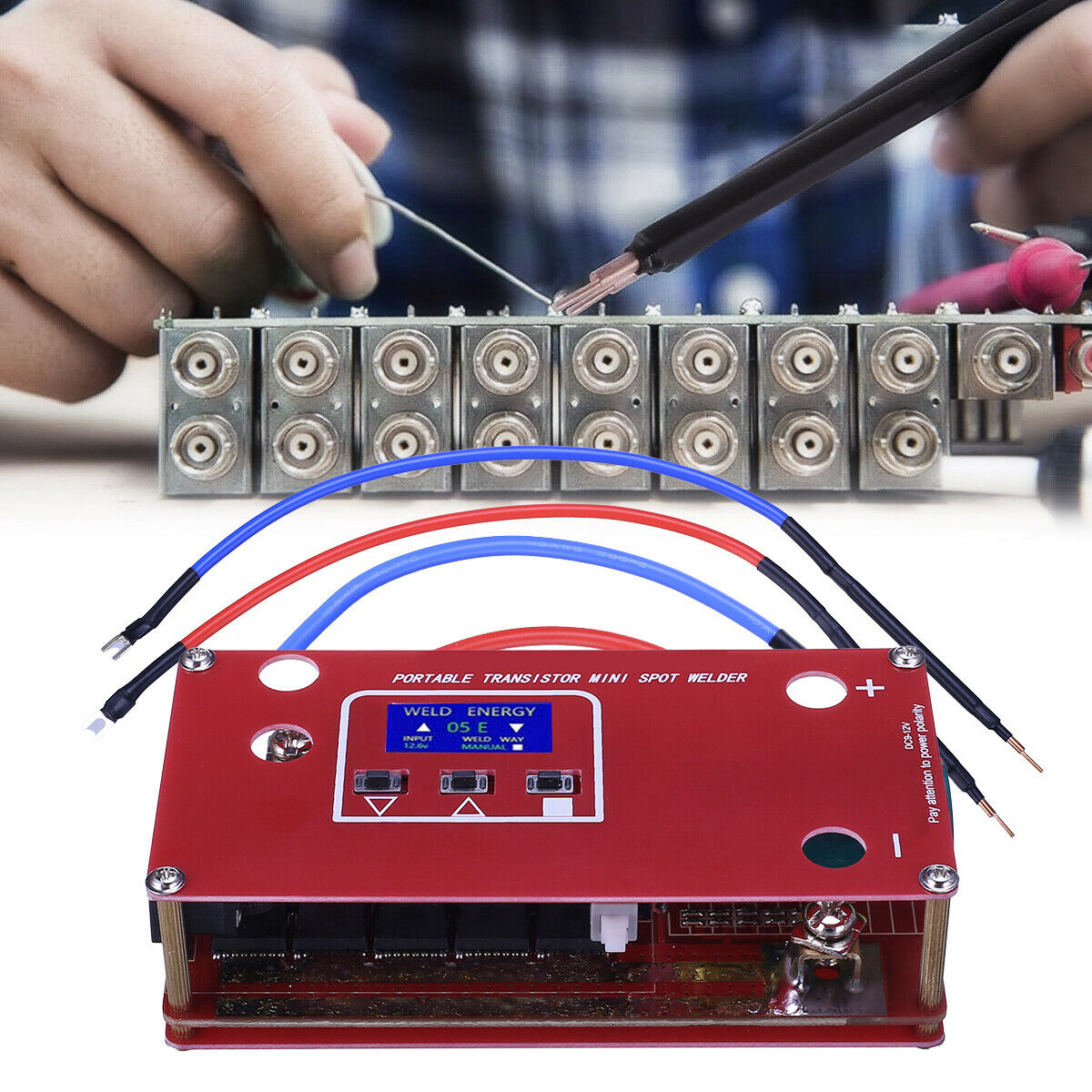

With an LCD display screen, can display welding parameters.

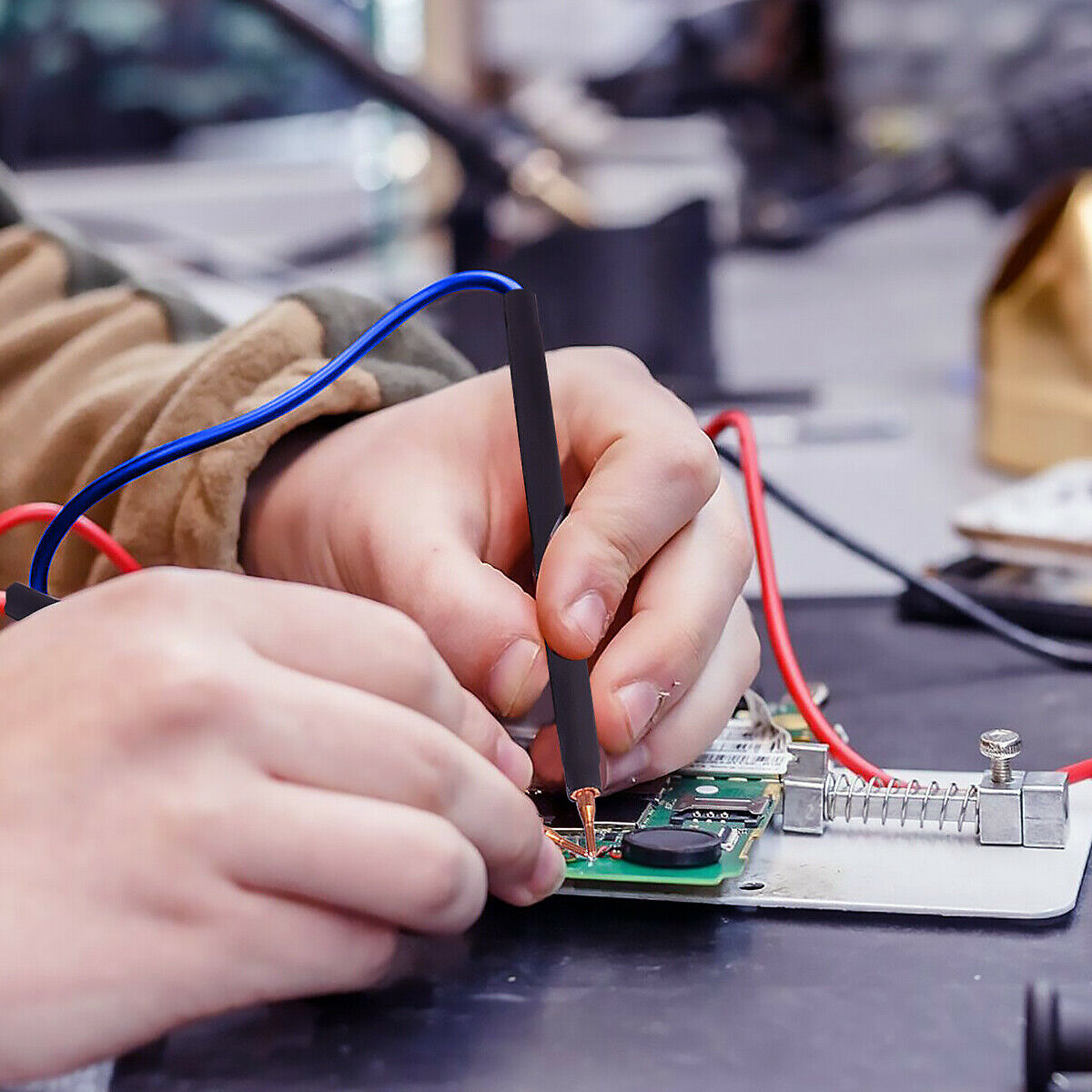

The welding pen and the input line are connected by U-shaped cold-pressed terminals, which are convenient for disassembly and replacement.

Using automatic touch welding mode, while retaining the manual trigger interface, you can choose according to your own use.

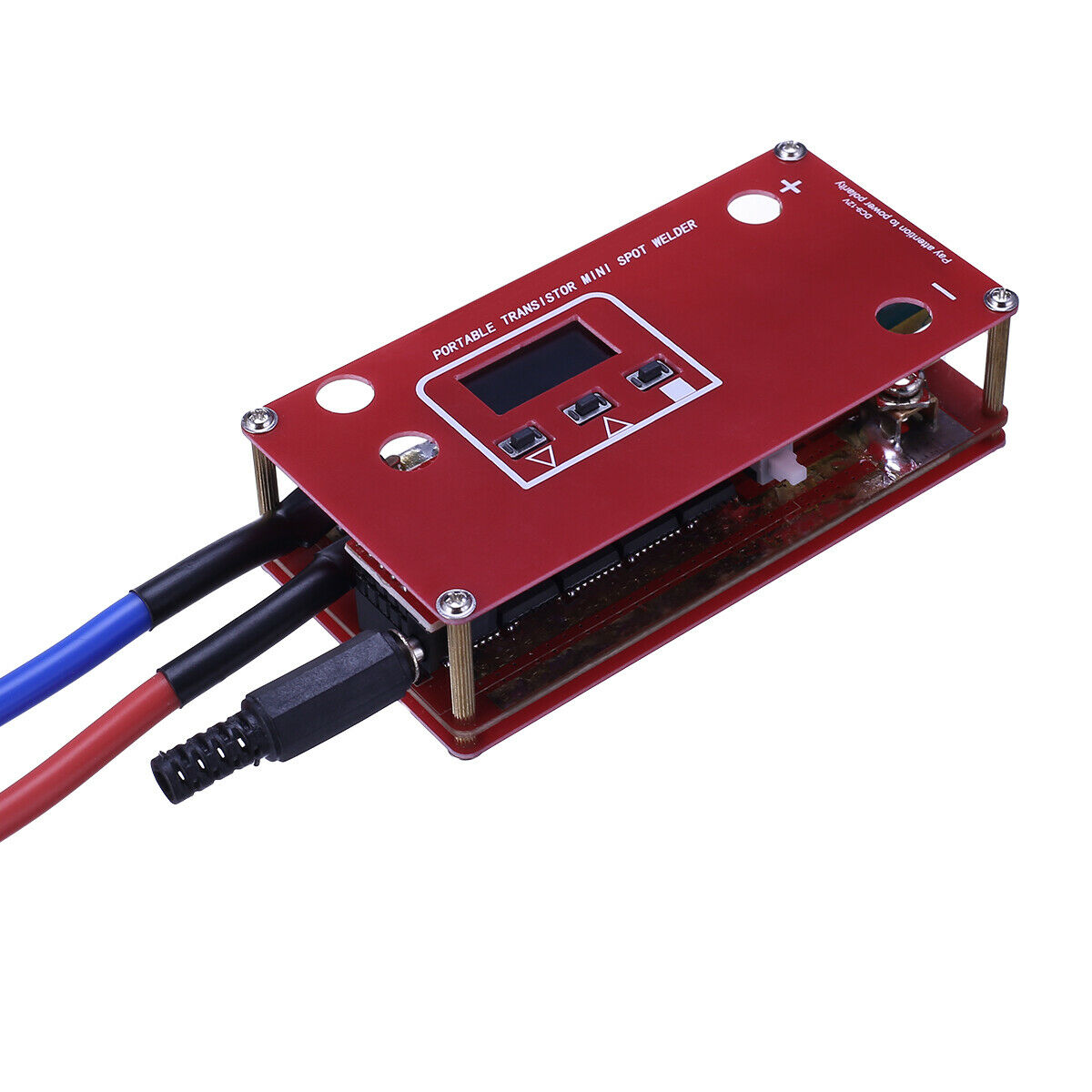

The power board uses 2 Gusi copper to increase the overcurrent capacity. Using 5 300A MOS tubes, non-disassembled MOS tubes.

The MOS tube driver adopts the imported special chip driver. The fastest MOS tube can be hit with 20nS. The switch is fast to prevent the explosion of the tube and the non-triode push-pull drive.

The MOS drive design adds a transient diode to protect the MOS and prevent the explosion of the tube.

10AWG multi-filament flexible wire is used for the welding pen line and the input line to increase the overcurrent capacity.

The controller is mainly for welding nickel-plated steel strips from 0.1mm to 0.12mm.

A 25V10000uF high-frequency low-resistance capacitor is added to the power input for energy compensation, which increases welding stability.

Product Features

A Wide Selection of Welding Power Supply: Lithium battery power supply or 12V car battery.

The controller is controlled by a single-chip microcomputer, and the output pulse is accurate to ensure the welding quality.

With an LCD display screen, can display welding parameters.

The welding pen and the input line are connected by U-shaped cold-pressed terminals, which are convenient for disassembly and replacement.

Using automatic touch welding mode, while retaining the manual trigger interface, you can choose according to your own use.

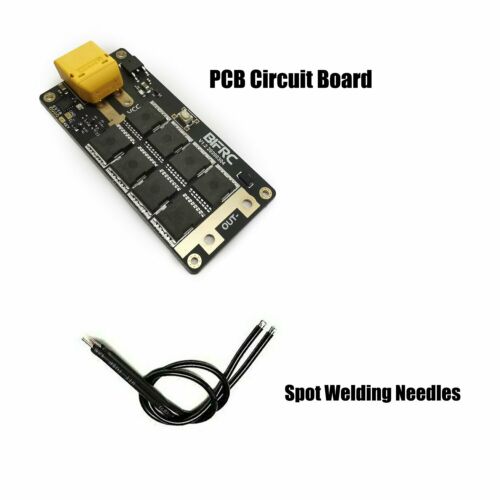

The power board uses 2 Gusi copper to increase the overcurrent capacity. Using 5 300A MOS tubes, non-disassembled MOS tubes.

The MOS tube driver adopts the imported special chip driver. The fastest MOS tube can be hit with 20nS. The switch is fast to prevent the explosion of the tube and the non-triode push-pull drive.

The MOS drive design adds a transient diode to protect the MOS and prevent the explosion of the tube.

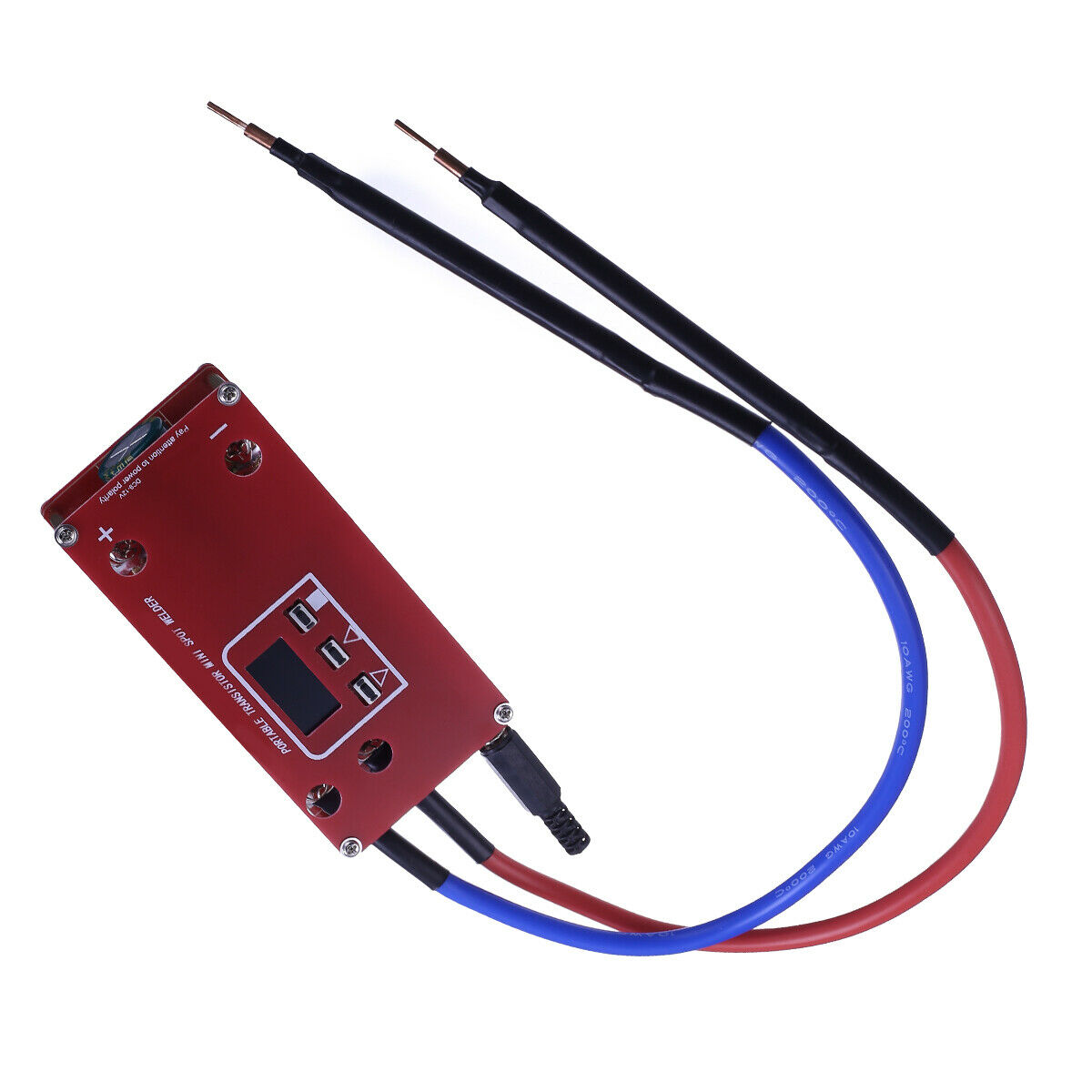

10AWG multi-filament flexible wire is used for the welding pen line and the input line to increase the overcurrent capacity.

The controller is mainly for welding nickel-plated steel strips from 0.1mm to 0.12mm.

A 25V10000uF high-frequency low-resistance capacitor is added to the power input for energy compensation, which increases welding stability.

Note:

Spot Welding Machine Set only, other accessories demo in the picture is not included.

Battery Selection:

1: 12V car battery from 25 to 40ah, requires good performance and small internal resistance

2: 4000 to 6000mAh 45C to 60C 3S model airplane lithium battery

3:30 to 35ah 12V capacity lithium battery pack

Welding materials:

Welding 0.1 to 0.12mm thick nickel-plated steel strip

Energy Setting:

The energy must gradually increase from 01, and the maximum should not exceed 50.

Exceeding the above conditions may cause damage to the controller.

Package Includes

1 x Controller

2 x of Welding Pen

2 x of Power Input Line (Red and Blue)

1 Pair of U-Shaped Cold-Pressed Terminal (Used to Connect to Input Power)

1 x User Manual

Shipping:

1. All orders ship within 24 hours after receiving your payment.

2. Tracking information will be sent to the buyer once we get the tracking number.

3. We only ship to eBay or PayPal address. PO. BOX Not Acceptable.

4. If you want us to ship to a different address, please contact us via eBay message after placing your order

Feedback:

1. We are really appreciated that all the customers can give us 5-star positive feedback. It will encourage us doing better, no matter the quality of the products or after sale service. We are learning more.

2. Please don’t give us neutral and negative feedback before contacting us. Don’t forget that good communication can solve all problems. Any questions, please feel free to send message to us first. We are always here to help you. Thank you very much.